STAUFF Kanban System

Suitable procurement solution with maximum process, quality and supply security

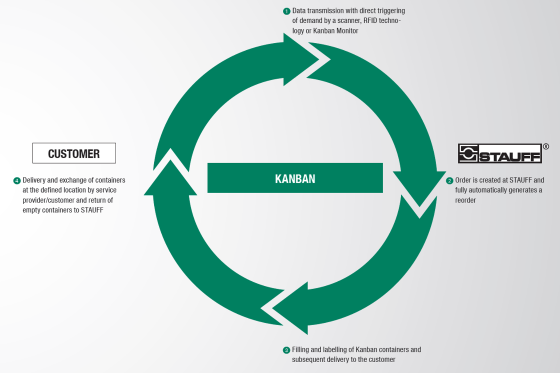

The STAUFF Kanban system offers an individually designed and thus precisely tailored procurement solution for specific customer requirements with maximum process, quality and supply security.

An optimal service solution for automatic replenishment is implemented, tailored to the type and range of articles, the working environment of the users/consumers and their needs. The focus is on maximum availability of the components in the right quantity, at the right place and at the right time.

A rolling container system provides STAUFF components "just-in-time" directly at the assembly site. In addition, it offers a high adjustment capability in the event of changes in requirements with maximum delivery and supply security and reduces customer-side inventories with low commitment of capital.

Manuel Träger is a Customer Success Specialist and, among other things, looks after the companies that are supplied in the kanban system at STAUFF Germany.

He has contributed his practical experience to the development of a new online tool:

The STAUFF Kanban Monitor was designed and developed together with kanban customers and the colleagues at STAUFF Digital.

The STAUFF Blog met Manuel Träger at his workplace in Werdohl Ehrenfeld and talked to him about the STAUFF Kanban Monitor.

Manuel, what are the most important functions of the kanban monitor and what does it offer our customers?

If I summarise the principle briefly: STAUFF customers can now view the status of individual containers in the delivery process online at any time and also check the availability of products for any repeat orders. Manual enquiries are no longer necessary.

What is the advantage for our customers?

The kanban monitor increases transparency and simplifies handling. In practice, the processes on the assembly line vary. This can be, for example, delivery bottlenecks for other components. With the kanban monitor, our customers have an overview of the delivery status of all containers at all times and can individually control the delivery circuits at short notice.

Colleagues like to talk about "all inclusive" when it comes to our kanban system. What is meant by this?

We offer the possibility of controlling. The kanban full service includes the analysis and documentation of consumption, a detailed monthly evaluation of the turnover rate for all containers and articles on request, suggestions for reducing or increasing stocks by adding more containers or eliminating articles in the sense of streamlining the assortment.

Manuel Träger, Customer Success Specialist at STAUFF Germany, elaborates on frequently made statements about kanban in general and the STAUFF Kanban System in particular:

As a kanban customer, I make myself dependent on one supplier.

Of course, it is advantageous to use the entire supply chain from a single source. However, our customers are free to use other suppliers at any time.

I am dependent on the technical equipment that is made available to me.

No. If, for example, a scanner should be defective, the user can simply reorder via the kanban monitor - in 24/7 mode and, thanks to the optimised website, even with a mobile device.

My value chain gets complicated when I work with manufacturers of other product groups in the kanban system as well.

Here too: No. Our kanban system can also be integrated into existing shelf systems of other suppliers. By using a STAUFF scanner, only STAUFF containers can also be reordered. The containers are also labelled with our logo, which ensures clear allocation.

Kanban is only worthwhile if I purchase large quantities.

For kanban, a regular turnover rate of the containers is required. Nevertheless, individual customer solutions can also be developed for lower turnover quantities and frequencies.

Newsletter Subscription

Receive automatic e-mail notifications about new posts on the STAUFF Blog