Steel is one of the most common metals in the world, used in a variety of applications, and it is extremely versatile. Carbon steel and stainless steel are two specific types of steel that are used to craft hydraulic components due to their durable and lasting qualities. Carbon Steel is an iron-carbon alloy and it is primarily made from iron and carbon with trace amounts of other elements to improve the metal's strength. Stainless steel is an alloy of iron with chromium and small amounts of other elements that improve its resistance to rust and corrosion.

Benefits

The benefits of Carbon Steel v Stainless Steel

Carbon Steel

- Manufacturing carbon steel is cheaper than most other steels, and accounts for a majority of steel production, making carbon steel components more affordable and widely available compared to others.

- Carbon steel components are extremely durable and strong making it easy to withstand high stress work environments without compromising its life span.

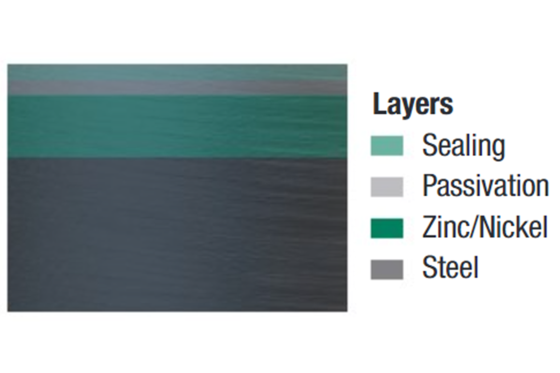

- Because carbon steel does not resist corrosion, many component manufacturers will apply different surface coatings to equip carbon steel components with additional protective properties. STAUFF utilizes a Zinc/Nickel surface coating that increases the components resistance to red rust and corrosion. The STAUFF Zinc/Nickel Surface Coating offers 1,200 hours of resistance to red rust and base metal corrosion. This coating gives the carbon steel components a high-quality look, resembling stainless steel. In addition, when it is combined with other metals there is less of a tendency for contact corrosion to take place.

Stainless Steel

Stainless steel components are resistant against corrosion and can be exposed to highly humid environments and exposure to chemicals, salt water, and other hydraulic fluids without it affecting the systems integrity.

Stainless Steel is designed to withstand high and low temperatures without disrupting the system's performance.

Offering a high quality look, these components are also hypoallergenic and hygienic, ensuring that they foster a safe and clean working environment without bacterial growth or having high levels of allergenic materials.

Because of their high durability, stainless steel components require reduced maintenance and replacements, making them an investment in longevity.

What are the Main Differences?

The 3 main differences between Carbon Steel and Stainless Steel

Strength: Carbon steel is known for its strength. It is ideal for applications that require structural integrity. Stainless steel is slightly lower in strength compared to carbon steel.

Corrosion Resistance: Stainless steel has excellent corrosion resistance and is ideal for high humidity environments, possible exposure to chemicals, and exposure to weather fluctuations. Carbon steel corrodes easily, however with special surface coatings, such as the STAUFF ZInc/Nickel Surface Coating, carbon steel components can offer corrosion resistance properties for an extended period of time. The STAUFF Zinc/Nickel Surface Coating has been tested in salt spray chambers and this surface coating protects against red rust and corrosion up to 1200 hours.

Affordability: As carbon steel is inexpensive to manufacture, it is also more affordable to purchase and widely available. Stainless steel tends to be more expensive, however due to its durability there are less maintenance and replacements costs over time.

What are Common Applications?

Common applications for Carbon Steel and Stainless Steel

Carbon Steel

- Due to its high resistance to wear and tear, carbon steel can be used in applications that require high levels of force, such as construction equipment and manufacturing applications.

- Carbon steel can handle high pressure levels making this material ideal for high stress work environments such as municipal equipment like recycling and garbage trucks, construction equipment, and agricultural equipment.

Stainless Steel

Due to stainless steel being highly corrosive resistant it is ideal for application in chemical processing, marine, and oil and gas/offshore. This also makes it ideal to be used in equipment that utilizes fertilizers, water, and other fluid, such as fertilizer sprayers and irrigation systems.

Stainless steel is known for its longevity and its hygienic nature making it ideal for applications in chemical processing and food and beverage processing, when cleanliness is essential for the safety and integrity of the hydraulic systems and workers.

Newsletter Subscription

Receive automatic e-mail notifications about new posts on the STAUFF Blog