Flow meter for flow, pressure and temperature

In places of use for construction, agricultural or forestry machinery, a general purpose flowmeter should be considered

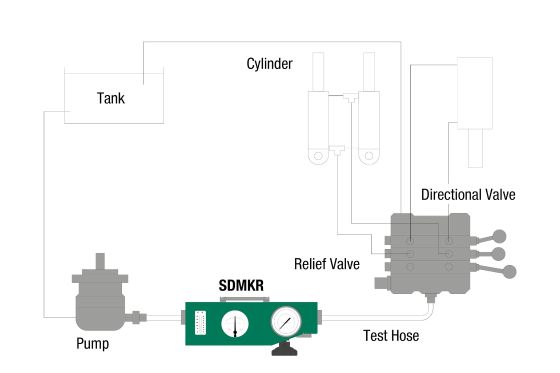

The SDMKR reversible flow meter from STAUFF has been developed for the rapid and accurate monitoring of hydraulic components and systems in mobile hydraulics systems. The unique design allows the simultaneous measurement of the three parameters most important for the proper functioning of the system: flow, pressure and temperature.

The device makes it possible for maintenance professionals to determine the performance of pumps, motors, valves or cylinders, as well as of complete systems, thereby ensuring that they function properly.

To test the performance of a hydraulic pump for example, the device is typically positioned upstream of the control valves.

Thanks to the compact, practical and yet robust design – with a sturdy steel frame, a removable protective cover and shockproof displays – the SDMKR is perfectly adapted to a wide variety of applications in construction, forestry and agricultural machinery, either on location or in the workshop.

The portable flow meters are integrated in the hydraulic circuit only for the duration of the system test. For this purpose, they are equipped as standard with BSP connection threads on the input and output, and can be installed in both pressure and return lines.

Product features of the flow meters type SDMKR

Flow: 2 ... 200 l/min

Pressure: 420 bar / 6091 PSI

Permits flow in the reverse direction

Makes it possible to increase the working pressure gradually and continuously up to 420 bar

Purely mechanical working principle

No internal or external power supply required

The central items in the new development are a flow meter with a visual display and a built-in thermometer, as well as a loading valve. To protect them against damage, all components are sunk deep into the solid aluminium housing – they are further safeguarded against damage by the steel frame. The loading valve makes it possible to safely increase the working pressure gradually and continuously up to 420 bar in order to provide a realistic simulation of normal machine operation. The pressure changes are documented by a stainless steel pressure gauge located at the inlet of the loading valve.

Two integrated burst discs act as internal safety mechanism, effectively protecting the device against accidental over-pressure. When the maximum pressure in the hydraulic system is exceeded, the discs break and the oil is transported through a bypass. The burst discs are located in a screw-in cartridge and can be replaced easily and quickly by the user if necessary.

The operation of the hydraulic tester is based solely on mechanical principles: it can be used independently of any internal or external power supply, thus providing maximum flexibility.

Unlike other comparable devices on the market, the SDMKR also permits flow in the reverse direction. This enables hydraulic cylinders to be lowered during the system test, for example. In this case, however, the flow meter does not provide a display value.

Flow meters type SDMKR in the STAUFF Online Shop

Rate and Comment

Rate posts in the STAUFF blog with just one click or leave feedback and suggestions as a comment – without registration

The editorial team of the STAUFF blog appreciates feedback and suggestions. Accordingly, readers can now not only rate all posts, but also leave comments as guests without prior registration

And it's that simple:

- Read or view the article.

- Scroll to the bottom of the page.

- Rate the post with just one click.

- Enter a comment.

- Submit your comment as a guest (only your name is required) or create a user account.

- After the comment has been reviewed and approved by the editorial team, it will be published online.

What do you think of this new feature?

Please share your opinion with us now using the rating and comments function!

Newsletter Subscription

Receive automatic e-mail notifications about new posts on the STAUFF Blog