Noise-reducing and vibration-damping NRC clamps

STAUFF NRC Clamps have been specially developed for noise-reducing and vibration-damping installation of pipelines with common outside diameters between 6 and 42 millimetres.

From the point of view of an acoustician, a hydraulic system is a classic example for the generation and transmission of sound. There are sound sources, for instance pumps. They stimulate the pipes, tubes and hoses connected to them. This creates structure-borne sound, which is further amplified by the pressure pulses in the hydraulic circuit. If this sound is then transmitted to metal structures such as machine housings or, in the case of mobile machines, body parts, these start to vibrate and the sound level increases further.

Clear task: Reducing the noise level

The result: The noise generated by hydraulic systems is disturbing for machine operators in production, for drivers of agricultural and construction machinery, passengers on cruise ships and for everyone else who is in the vicinity of the systems. Not only that, the noise can make you sick. Noise-induced hearing loss is one of the most common occupational diseases.

But how can the sound level be reduced?

The manufacturers of the machinery or the hydraulic unit can, for example, use quieter pumps, optimise the flow of the system or design noise protection systems and machine enclosures that are not prone to vibrations. But they can also have it easier (and still achieve a better effect) if they make use of the principle of acoustic decoupling.

This means: You do not prevent the sound from originating, but rather its expansion via the pipe and tube network in the form of structure-borne sound – because this is the one that generates the "unpleasant" pulsating noises.

In fact, this can be done comparatively easily by dispensing with conventional pipe and tube clamps that fix the line with pressure and thus transfer the vibrations (and with them the sound) from one component (the pipe or tube) to the other (the machine housing or the vehicle body).

Well known: Noise damping with NRC pipe clamps

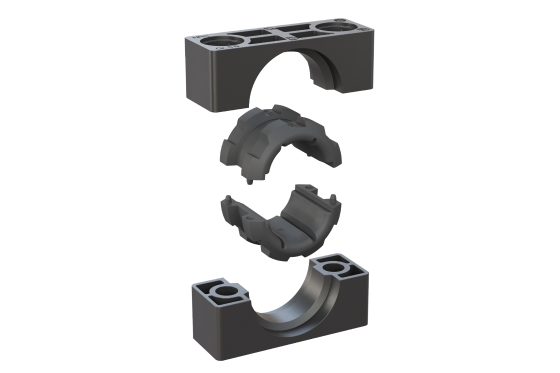

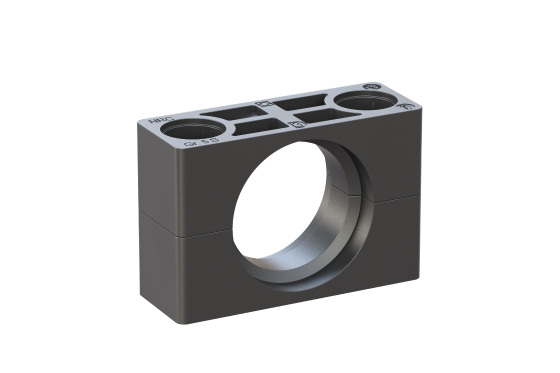

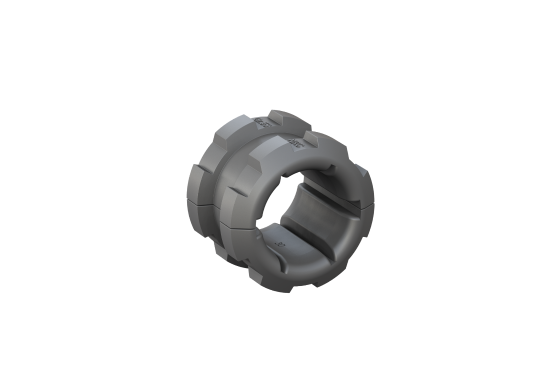

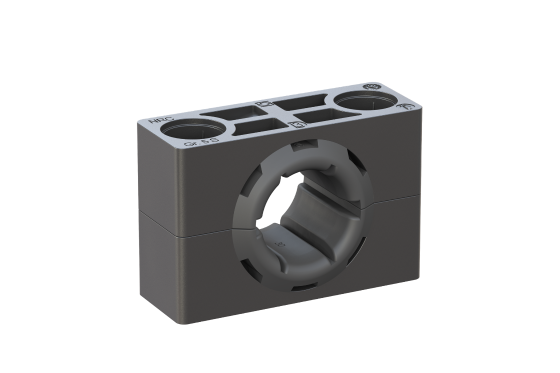

Instead, the designer who wants to reduce the noise level of the hydraulic system should use the NRC pipe and tube clamps from STAUFF. In contrast to the standard clamp design according to DIN 3015 and other designs made of plastic and metal commonly available on the market, NRC clamps have a specially shaped two-part elastomer insert integrated into the clamp body made of Polypropylene or Polyamide. It decouples the pipeline from the surrounding structure, thus reducing the transmission of vibrations in both directions and noticeably reducing the noise level. The NRC clamps are compatible with regular mounting hardware made of steel and stainless steel and can be easily replaced or retrofitted if necessary.

Transfer of the principle to hose clamps

The STAUFF developers have now transferred this principle to hose clamps. The NRC clamp body has been retained, but the elastomer insert has been adapted to hydraulic hoses in terms of its contour and elasticity. The result: NRC-H series clamps. In concrete terms, this means that the hose retains a certain defined "freedom of movement" in the radial direction, so that its outer diameter can change to the necessary extent due to the pressure pulsation. Nevertheless, it remains securely in position, it is not "stressed" and the transmission of structure-borne noise is avoided.

The development in detail

In contrast to the NRC pipe clamps, the two-piece insert of the NRC-H hose clamps protrudes slightly beyond the clamp body on both sides and thus offers the hose a significantly larger contact surface.

Other design features include large outlet radii and longitudinal ribs in the elastomer insert. They allow the compensation of changes in the diameter of the hose while at the same time ensuring gentle yet stable fixation.

Risk of wear and damage is also reduced

The type NRC-H hose clamps from STAUFF not only reduce the noise level. Because they prevent the propagation of vibrations, they also minimise wear on the hose, which is usually the more important aspect in practice.

Example: Manufacturers of mobile machinery have found that constant micro-vibrations at the hose-clamp connection can lead to melting at the support points, which accelerates hose wear. This damage pattern can be avoided – as current tests in the STAUFF research laboratory show – by using NRC-H hose clamps.

Conclusion and outlook

With type NRC-H hose clamps, which are currently being tested in the field by several well-known OEM machinery, equipment and vehicle manufacturers and are about to be launched as a standard product, STAUFF is not only making another important contribution to reducing the noise of hydraulic systems, but in particular to increasing the service life of hose assemblies.

Get in touch with Hendrik Schmücker now

Do you have any questions about the NRC concept for hydraulic pipes, tubes or hoses? Then please use the form below to contact Hendrik Schmücker. We look forward to hearing from you!

Rate and Comment

Rate posts in the STAUFF blog with just one click or leave feedback and suggestions as a comment – without registration

The editorial team of the STAUFF blog appreciates feedback and suggestions. Accordingly, readers can now not only rate all posts, but also leave comments as guests without prior registration.

And it's that simple:

- Read or view the article.

- Scroll to the bottom of the page.

- Rate the post with just one click.

- Enter a comment.

- Submit your comment as a guest (only your name is required) or create a user account.

- After the comment has been reviewed and approved by the editorial team, it will be published online.

What do you think of this new feature?

Please share your opinion with us now using the rating and comments function!

Newsletter Subscription

Receive automatic e-mail notifications about new posts on the STAUFF Blog