Fancy a Deep Dive?

Read the full Title Story in the Fluid Magazine now

Electrification of Construction Machinery

For over 60 years, STAUFF has been working to reduce noise and vibrations in hydraulic systems. As early as the 1960s, we took an important step by developing our plastic clamps for securing hydraulic lines. Today, with the electrification of mobile machines, the reduction of noise and vibrations is more important than ever. Hydraulics are increasingly coming into focus as a source of noise – and this is exactly where our innovative solutions come in.

What changes for the hydraulic system?

Essentially, one may ask: “What actually changes for the hydraulic system?”. When construction machinery is no longer powered by combustion engines but by electric motors, little changes for the hydraulics at first. Only the drive type of the pump is altered. The system continues to operate in the same way.

But it’s not quite that simple. The electric motor eliminates one of the main sources of noise in construction machinery. The result: The hydraulic system and its operational noise become the loudest elements in the work process.

From this, we at STAUFF draw a conclusion: We also want to continue reducing vibrations and noise. For the lowest possible stress during work and progress that supports a more sustainable future, rather than hindering it.

Sources of Hydraulic System Noise

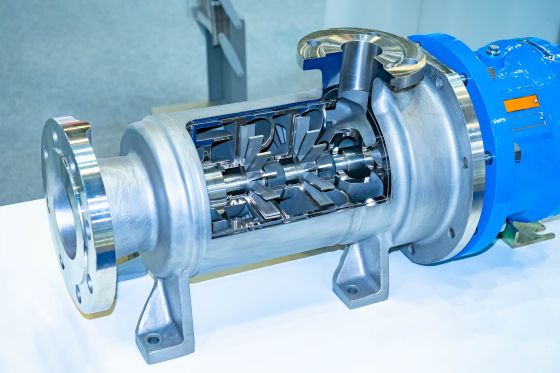

Noise and vibrations in hydraulic systems have two main sources: the operating noise of the pump and the movement of the hydraulic fluid. This movement generates pressure impulses, causing vibrations and structure-borne noise. In electrically powered construction machinery, which is generally quieter than its conventionally powered counterparts, the hydraulics emerge as the dominant noise source alongside operational noise.

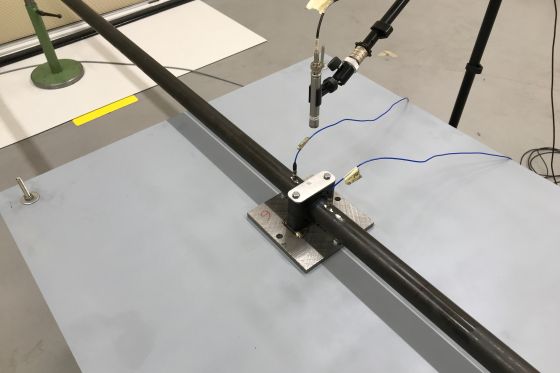

On the pictures below you can see the acustic laboratory where the noise of moving hydraulic fluids can be precisely determined while other causes of noise stay outside of this room.

Acoustic Decoupling at STAUFF

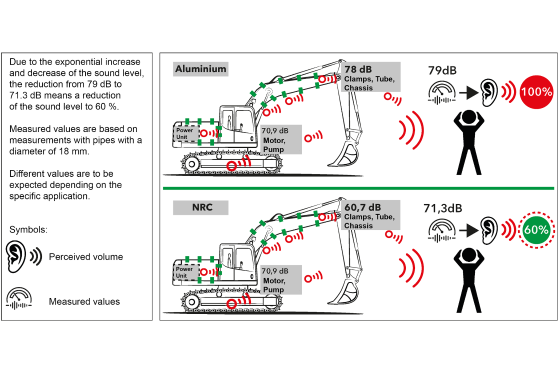

An essential approach to reducing vibrations and noise is acoustic decoupling. This prevents vibrations and structure-borne noise from spreading unchecked through lines and components. Our plastic clamps have made a significant contribution here from an early stage. Over the years, we have continuously developed this technology to achieve even greater damping effects, which you can see visualised on the picture below

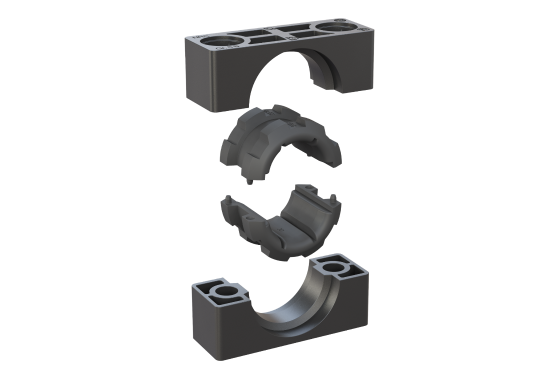

The Innovation: STAUFF NRC Clamp

One of our most important developments in this area is the NRC clamp (“Noise Reduction Clamp”). It was specifically designed for applications where strong vibrations and noise are an issue – such as in shipbuilding or electrically powered construction machinery. The specially shaped elastomer insert reduces contact between the pipe and the clamp, significantly damping vibrations. This helps reduce noise emissions considerably.

Minimising Vibrations and Wear

In addition to reducing noise, our NRC-H clamps offer an extra function: They protect hydraulic hoses from wear. Constant micro-vibrations can damage the material at the clamp points and place a heavy load on the hose. By using elastomer materials, this process is prevented, which not only lowers the noise level but also extends the hose’s service life.

A Holistic Approach to Noise Reduction

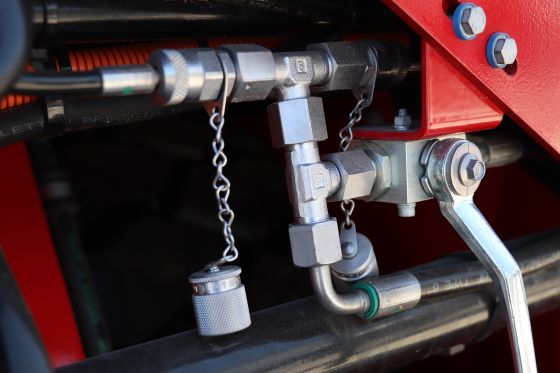

However, our work goes beyond the development of individual products. At STAUFF, we consider the entire hydraulic line system to minimise noise and vibrations. Flow noise, which is caused by pressure fluctuations and turbulence, can be significantly reduced by optimising the routing of lines and using appropriate components. Our STAUFF Line programme supports OEMs from the conceptual and planning phase to develop optimal line solutions.

FAQs

What is the NRC clamp and where is it used?

The NRC clamp (“Noise Reduction Clamp”) is a specially developed clamp designed to reduce vibrations and noise in hydraulic systems. It originated in shipbuilding and is now also used in construction machinery and other mobile working machines.

How do STAUFF products help reduce noise in hydraulic systems?

Can I retrofit the NRC clamp in existing systems?

Yes, the NRC clamp is compatible with conventional mounting accessories and can be easily retrofitted into existing systems.

Why is reducing vibrations important for hydraulic hoses?

Vibrations cause material fatigue and wear in hydraulic hoses. Our NRC-H clamps reduce these vibrations, extending the service life of the hoses.

How does STAUFF support OEMs in designing pipe systems?

We provide comprehensive advice to OEMs during the planning and development phase. We optimise the entire piping system in terms of flow behaviour, pressure fluctuations, and noise reduction to find the best possible solution.

Newsletter Subscription

Receive automatic email notifications about new posts on the STAUFF Blog