"We have completed a technology shift in hydraulic connections"

The Slovenian hydraulic service provider Pisnik from Vuzenica near Maribor was one of the first users of both STAUFF Form and STAUFF Form EVO. In this interview with the STAUFF Blog, Jernej Pisnik, the company's future Managing Director, talks about the development of the Slovenian hydraulics industry and his experiences with STAUFF Form.

Mr Pisnik, you used STAUFF Form in a very large project shortly after its introduction in 2015.

At that time, we manufactured the complete piping for a large hydraulic press and assembled it on site in Canada using STAUFF Form. Since then, we have regularly used the forming system when piping high-pressure systems.

Your company has been growing steadily for years – first with hydraulic service, now also with your own products and power units and soon even your own range of machines. In just seven years, the number of your employees has doubled. Is that representative for the hydraulics market in Slovenia?

We are growing faster than the rest of the country. But it is true: Slovenian mechanical engineering, including the supplier industry, has a good reputation and a long tradition. We work with many customers in Germany and especially in Austria – the national border is only twenty kilometres away and Graz about fifty. So the distance is short and there is no language barrier for us either.

You opted for the STAUFF Form tube forming system at an early stage – why?

We work intensively with manufacturers and users of hydraulic presses. Tube forming systems are a must there. And the automotive industry is also strongly represented in Slovenia. It also prefers formed connections, for reasons of safety and availability. So the decision was obvious.

... and you have not regretted it?

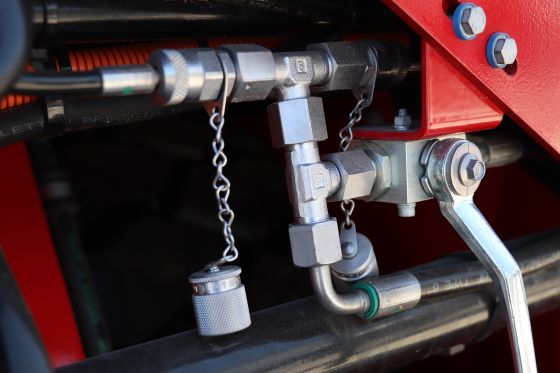

No. We have really completed a change in technology. In 2017, we still supplied many hydraulic systems with welded connections; that's over. Forming with the STAUFF Form system is cleaner and also more cost-effective. We now also use this technology frequently for the piping of smaller units.

Now, as you know, there are also other manufacturers of tube forming systems. What speaks in favour of STAUFF from your point of view?

We have been working in partnership with STAUFF for many years and know: We can rely on the machines and on every single component. The system is easy to assemble and now, with the EVO version, we are also absolutely competitive in terms of price. We also source other components such as clamps, hydraulic filters and testing equipment from STAUFF. Single sourcing from a full-range supplier is simply efficient.

About the STAUFF Form EVO Tube Forming System

Machine-Assisted Forming of Tube Ends in Hydraulics

The STAUFF Form tube forming system was first presented in 2015. Since the beginning it has undoubtedly been one of the most efficient solutions available on the market for connecting metric tubes. In addition to its simplicity, it convinces with a high degree of safety, reliability and reproducibility.

With STAUFF Form EVO, STAUFF now presents the latest generation of the tube forming system, which is characterised by an increased level of efficiency and versatility as a result of continuous optimisation.

STAUFF Form EVO has been designed as standard for seamless cold-drawn precision steel tubes as well as stainless steel tubes with dimensions between 6 x 1.5 mm and 42 x 4 mm in the Light Series and between 6 x 1.5 mm and 38 x 6 mm in the Heavy Series.

If required, parameters for alternative materials are available upon request and can be added by the manufacturer or via the optional cloud connection module integrated in the machines.

Newsletter Subscription

Receive automatic e-mail notifications about new posts on the STAUFF Blog