What types of contamination can enter the hydraulic system when "breathing"?

Episode 2 of the STAUFF Miniseries "Is Your Hydraulic System Breathing Properly?"

Air is not always clean, and certainly not in nature or at a construction site. Silica breathers bind moisture and prevent the ingress of other undesired substances. Our engineers tell you which these are:

Did you know: You can turn on subtitles by clicking the CC button at the bottom of the video.

Watch this and all other episodes of this STAUFF Minseries on Youtube instead.

Against which foreign substances do silica breathers protect the hydraulic system?

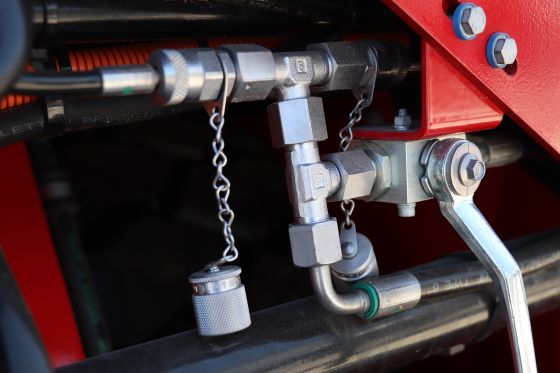

Firstly, silica breathers protect the hydraulic system against regular dust, sand, pollen, small insects and moisture that would enter into the hydraulic system through an unprotected opening during “breathing”. Mobile machines, however, often have to run in particularly challenging circumstances. Agricultural and forestry machinery, construction machinery in building construction and civil engineering, transport vehicles, and tunnel boring machines or bucket excavators in surface mining have to be protected primarily against particle contamination, such as coarse stone or soil dust. These have an abrasive impact on the hydraulic system and damage it, for example the sealing faces of valves and pumps.

Failure analyses show that 70 to 80 per cent of all machine failures are caused by contamination in the hydraulic oil!

The STAUFF range of silica breathers includes products that protect hydraulic systems even during use in extreme conditions. Bucket excavators in surface mining are an application example for the high-end series SDB. They have to continuously deliver high performance with minimum downtime in 24/7 operation, and in a very dirty environment. Any unplanned failure of these gigantic machines would have serious consequences because the excavators are positioned at the start of the entire process and value chain of raw material production. The use of desiccant units offers the greatest benefit with minimum expenditure, especially as the systems are operated outdoors, i.e. with temperature fluctuations and – depending on the climate zone – high humidity, which would enter into the hydraulic system during breathing.

The SDB series is also used in heavy-duty transport vehicles from a Chinese manufacturer and improves the availability of the hydraulic system. Depending on the model, the vehicles weigh at least 35 tons and are used primarily for transporting heavy ship segments at shipyards. The drive of the transport vehicles as well as the shock absorption/suspension and various work functions, especially lifting, rely on hydraulics. The silica breathers are used in all hydraulic systems of the vehicles – in the drive circuit as well as in the work hydraulics and in the shock absorption/suspension. Another application is for tunnel boring machines which are operated over a period of several weeks at a time, in a very dusty environment with highly difficult access.

High-quality silica breathers make the users’ work much easier: Operators of mobile machines or their service providers do not have to worry about the quality of the air entering the hydraulic system, but can rest assured that the “breathing” has no negative impact on the availability of the respective mobile machine.

Do you already use silica breathers in hydraulic systems?

Then share your experiences and leave a comment below this post.

Newsletter Subscription

Receive automatic e-mail notifications about new posts on the STAUFF Blog