Preparing pipes and tubes in hydraulics

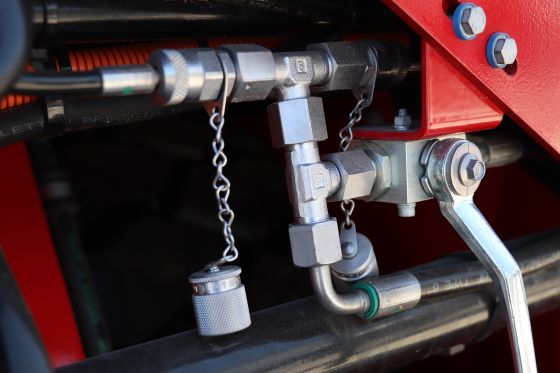

Preparing hydraulic pipes and tubes is a crucial step in hydraulic technology. Defective or improperly prepared pipes and tubes can significantly shorten the lifespan of pipe connections and lead to dangerous leaks. These leaks pose a threat to people, machines, and the environment, especially due to oil loss. In this article, we will identify common mistakes in preparing hydraulic pipes and tubes and provide valuable tips on how to avoid them.

Improper storage and handling of pipes and tubes

Improper storage and handling of pipes and tubes can lead to significant damage. Scratches, dents, and nicks can occur during transport, storage, or handling. When pipes and tubes are pulled from storage, cut to length, and stored again, burrs and cutting debris on the cut pipes and tubes can damage other pipes and tubes.

Dents and nicks at the pipe and tube ends are particularly problematic. These occur when excessive force is applied to the pipe or tube during transport, dragging the pipes and tubes along the ground, or dropping them when cutting to length. To avoid this, pipes and tubes should always be handled carefully and properly stored. It is also recommended to always seal the pipe and tube ends with a plug or cap to protect them from contamination. This is especially important after processing.

Errors when cutting pipes and tubes

A common mistake is processing the delivered pipe or tube (usually 6 meters long) without cutting it to length first. A rule of thumb is to cut at least 10 mm from the manufacturer's or supplier's separation cut. In case of visible damage, a thorough visual inspection is necessary.

The pipe or tube end should always be cut at a right angle (90°) to the pipe or tube axis. The maximum angle deviation should not exceed ±0.5° to the pipe or tube axis. For precise execution, it is recommended to mark the cutting point beforehand and check it with a square.

Another common mistake is using the wrong tool. When working on hydraulic pipes and tubes, a guided hacksaw with a metal saw blade should be used. Pipe cutters or angle grinders are not suitable and can damage the material.

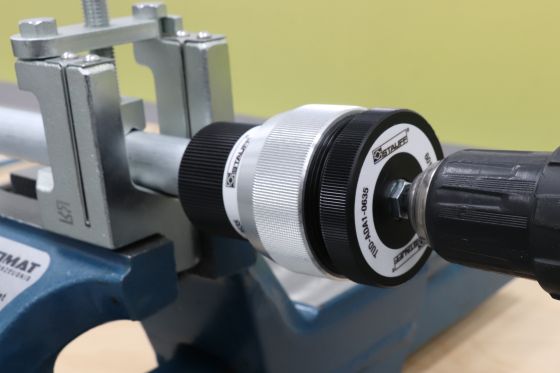

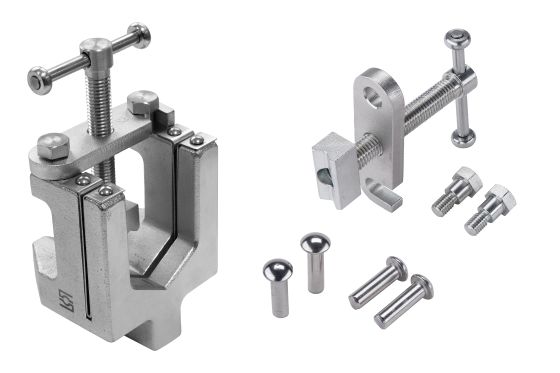

At STAUFF, we offer the right products for these tasks. With our bending and cutting devices, mistakes can no longer happen

Errors when deburring pipes and tubes

An often overlooked step is deburring the pipes and tubes. If pipes and tubes are not deburred, burrs and cutting debris remain on the pipe or tube, which can affect the seal integrity. Pipes and tubes must be deburred both inside and outside, with a slight chamfer of a maximum of 0.2 x 45° applied.

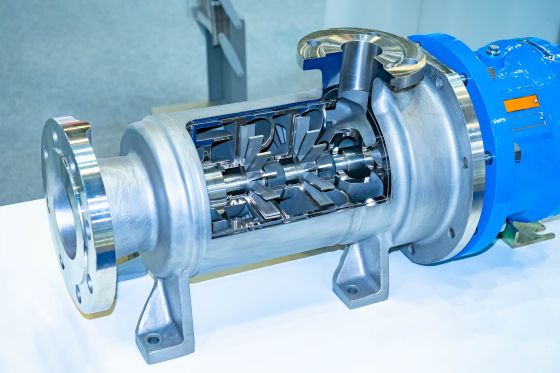

Special pipe deburrers should be used for deburring pipes and tubes. Flat files are only suitable to a limited extent, as they are more intended for smoothing surfaces and sharpening straight edges. Round files are only suitable for working on round surfaces and inner radii. It is also essential to clean off contaminants such as metal shavings and paint or lacquer residues afterward. Metal shavings left in the system can damage contamination-sensitive components such as pumps and valves and cause machine downtime.

STAUFF also offers the right products for deburring pipes and tubes:

STAUFF is your partner

Proper preparation of hydraulic pipes and tubes is essential for safety and efficiency in hydraulic technology. By recognizing and avoiding the most common mistakes, you help extend the lifespan of pipe connections and prevent dangerous leaks. Invest in high-quality tools and pay attention to careful work practices to ensure the optimal functionality of your hydraulic system. At STAUFF, we are happy to assist you with any questions on this or other topics. Order our products in the online shop or contact us.

FAQs

Why is proper storage of hydraulic pipes and tubes important?

What are common mistakes when cutting pipes and tubes?

Common mistakes include insufficient preparation, incorrect angles when cutting, and the use of unsuitable tools.

Why is pipe and tube deburring important?

Deburring removes sharp edges and contaminants that can compromise the seal integrity of pipe connections and lead to leaks.

Newsletter Subscription

Receive automatic e-mail notifications about new posts on the STAUFF Blog