The invisible danger in hydraulic systems

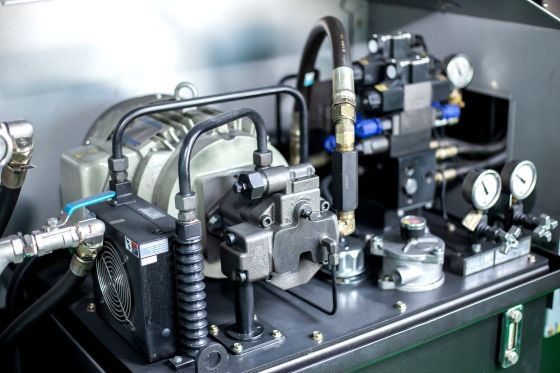

Cavitation is an underestimated risk in many hydraulic systems. It occurs when vapour bubbles form in a flowing liquid and suddenly collapse under high pressure. The consequences are often serious: damage to pumps, valves and pipes, loss of efficiency and high repair costs.

In this article, you will find out exactly what cavitation is, where it occurs in the hydraulic system, how it can be avoided - and how STAUFF can support you with suitable components and services.

What is cavitation?

Cavitation refers to the formation and sudden collapse of vapour bubbles in a liquid. It occurs when the pressure in a liquid drops below the vapour pressure - for example at bottlenecks or in the suction tract of a pump.

If the pressure rises as the flow continues, the bubbles implode. This creates pressure surges and shock waves that attack the material and cause long-term damage.

To summarise:

Occurs due to local pressure drop below the vapour pressure

Leads to the formation of vapour bubbles

The collapse of the bladders causes high mechanical stress

Where does cavitation occur in hydraulic systems?

It typically occurs at points in the system where pressure losses or abrupt flow changes occur. Critical zones include

Pumps - especially in the suction area if the inlet pressure is too low

Valves and throttle points - due to rapid opening, closing or unfavourable flow routing

Pipes and connections - if cross-sections are too narrow, incorrectly dimensioned or with sharp bends

Filters - if they are dirty and obstruct the flow

Return lines - especially with insufficient flow stabilisation in the tank area

Many of these problems are not caused by incorrect operation, but by inadequate planning or neglect of maintenance.

Why is cavitation dangerous?

The consequences range from slight material erosion to serious damage to central components.

Typical effects are

Mechanical erosion: The collapse of the bubbles generates very high pressures at certain points, which can detach material from surfaces.

Wear on components: Pumps, valves and pistons are particularly at risk.

Noise and vibration development: Cavitation is often initially perceptible acoustically - as crackling or hissing.

Loss of performance and system instability: Air bubbles and pressure fluctuations can reduce efficiency.

Increased maintenance and repair costs: Damage caused by cavitation is usually irreversible and requires replacement of the affected components.

In many cases, the damage occurs gradually and is only recognised late - when the failure is already inevitable.

How can I avoid cavitation?

The best strategy against cavitation is targeted prevention. Both the design of the system and ongoing maintenance play an important role here.

Design measures:

Sufficient dimensioning of pipes and pumps

Avoidance of sharp deflections and cross-section constrictions

Optimisation of the tank design for flow calming and ventilation

Operational measures:

Ensuring a stable supply pressure at the pump

Regular replacement and inspection of the filter elements

Monitoring the oil temperature and viscosity (too high temperatures favour cavitation)

Venting the system to prevent the formation of gas bubbles

Additional recommendations:

Use of condition monitoring for early detection

Documentation and trend analysis of operating parameters

The combination of these measures not only reduces the risk of cavitation, but also increases the operational reliability of the entire system.

STAUFF products and services to prevent the problem

STAUFF offers a wide range of components and services that specifically help to prevent cavitation - both in system planning and during operation.

Component solutions:

Filter technology: High-quality pressure, return and suction filters prevent contamination and reduce pressure losses

Pipe and hose connection systems: Precisely manufactured connection technology with flow-optimised internal geometries

Tank components: Return flow distributor, dehumidifier, vent filter and matching level and temperature gauges

Services:

Application consulting and engineering: Support in the flow-optimised design and optimisation of systems

Condition monitoring: Mobile and stationary particle measuring devices for monitoring oil cleanliness

Fluid analyses: meaningful diagnostics on the condition of the hydraulic fluid

With STAUFF, you not only benefit from high-quality products, but also from technical advice and long-term support throughout the entire system life cycle.

Better planning, better protection - your advantage with STAUFF

Cavitation is not an unavoidable phenomenon, but can be largely avoided through foresighted planning and targeted measures. If you act early, you will save money in the long term, reduce downtimes and ensure the performance of your hydraulic system.

We are at your side as a competent partner - with experience, system understanding and solutions that make the difference.

Feel free to contact us - we will advise you personally and on a project-specific basis.

FAQs

How can I recognise cavitation in operation?

Cavitation often manifests itself through unusual noises (e.g. hissing or crackling), vibrations and decreasing performance or rising temperatures in the system.

Can cavitation be completely prevented?

How quickly does cavitation cause damage?

That depends on the intensity. In severely affected systems, damage can occur after just a few hours, in others only after weeks or months.

Which STAUFF products are suitable for preventing cavitation?

Filters, tank components, connection technology and diagnostic tools in particular help to prevent cavitation. A systematic analysis helps to select suitable solutions.

How much does it cost to repair cavitation-related damage?

The costs vary greatly - from the replacement of individual valves to the complete replacement of pumps or units. Prevention is always more economical.

Newsletter registration

Register now and don't miss any new articles!