What is the STAUFF twin series?

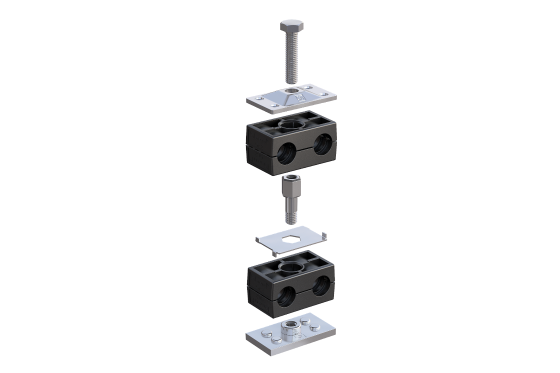

How does stacking assembly work?

A particularly space-saving variant is the so-called surface-mounted installation, in which several layers of clamps are installed directly on top of each other. As a rule, STAUFF recommends a maximum of three layers to ensure stability and the required retaining forces, even at the upper levels. The stability of the structure must be checked individually by the user and evaluated in the overall context of the system and the expected mechanical loads!

Example structure in detail

Fastening with a STAUFF stacking bolt, which is firmly bolted into the substructure. This screw has an internal thread in the head.

Middle layer:

Another stacking bolt is bolted into the internal thread of the lower screw.

Top layer:

Complete the installation with a standard external or internal hexagon head bolt.

Locking plates are used between the individual layers to stabilise the connection and prevent the surface-mounted bolts from loosening automatically.

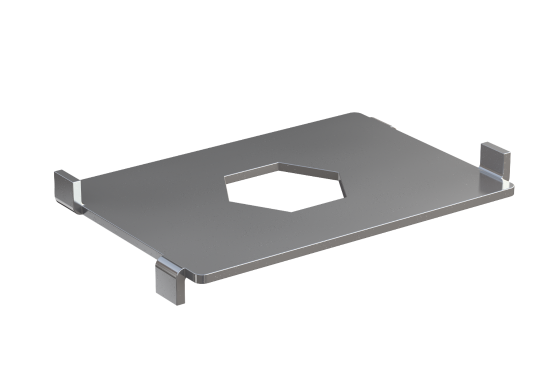

Locking plates: SI vs. SIV

STAUFF offers two variants of locking plates for stacking assembly:

SI - Safety Locking Plate

Interlocks with the respective clamp body underneath

Secures the stacking bolt against self-loosening

Also enables the upper clamp position to be rotated

Cost-effective solution for flexible applications

SIV - Safety Locking Plate with Anti-Twist Feature

Interlocks with the respective clamp body underneath and above

Secures the stacking bolt against self-loosening and at the same time prevents the top layer from twisting

Ensures a uniform appearance

Ideal for applications with high visual or mechanical requirements

What's new?

Until now, the SIV locking plate was available in two separate versions for size 1D (with M6 thread) and for sizes 2D and 3D (with M8 thread). Clamps of sizes 4D and 5D could not be secured against twisting for structural reasons.

This has now changed:

A structural adaptation of the SIV plate enables it to be used for sizes 2D to 5D. This means that, for the first time, larger twin clamps can also be used in surface-mounted installation without twisting.

New material designation:

The previous designation SIV-2-3D-... has been replaced by SIV-2-5D-....

Standard materials:

Steel, zinc/nickel-coated (SIV-2-5D-W3)

Stainless steel V4A (SIV-2-5D-W5)

Other variants available on request

Advantages of the new SIV securing plate

The new securing plate not only provides more stability, but also more flexibility:

Standardised plate for all sizes from 2D to 5D

Combination of different clamps possible (e.g. size 5D at the bottom, size 3D above, size 2D at the top)

Ordered alignment of all layers

Reduced storage costs thanks to universal components

Improved appearance and installation quality

This innovation makes stacking assembly with STAUFF clamps even more versatile and efficient - especially in demanding applications.

FAQs

What is the STAUFF twin series?

How many clamp layers are possible for stacking assembly?

STAUFF recommends a maximum of three layers - depending on the load and application.

What is the difference between SI and SIV retaining plates?

In contrast to the simpler SI retaining plates, SIV retaining plates prevent the top layer of clamps from twisting.

What sizes does the new SIV plate support?

All sizes from 2D to 5D - with just one universal plate.

Is the retaining plate also available in stainless steel?

Yes - as variant SIV-2-5D-W5 made of V4A stainless steel.

Can I fit clamps of different sizes on top of each other?

Yes - thanks to the new SIV plate, installation of sizes 2D to 5D with anti-twist protection is possible without any problems.

Newsletter subscription

Subscribe now and don't miss any new articles!